5 Reasons Why You Should Carefully Choose a Metal Stamping Provider

Selecting stamping die manufacturers calls for a lot of consideration. The stakes are high because the chosen provider will affect the efficiency and quality of your manufacturing process. This choice is very important, so let's talk about what you should think about when making the decision.

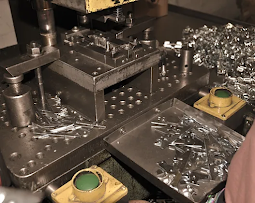

Accuracy and Standards Count

Metal stamping depends much on accuracy and quality. A metal stamping services

provider lacking careful attention may create components that fall

short of your exact specifications, resulting in expensive mistakes. The

smallest deviation in a stamped product can make it useless or possibly

dangerous. Make sure the supplier has strict quality control policies

in place and employs cutting-edge technology. Industries with extremely

strict standards and negligible room for error require a total

commitment to quality and precision.

Knowledge and Ability

Metal stamping heavily relies on experience and expertise. Decades of experience allow providers to offer an extensive pool of knowledge and problem-solving ability. They can see possible problems and take care of them before they become more serious. Their knowledge also enables them to provide practical advice on cost-cutting strategies, design changes, and material choices.

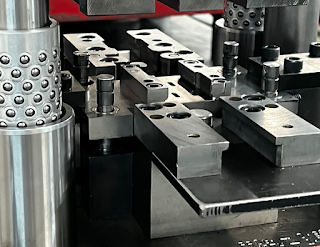

Modern Equipment and Technology

The result directly depends on the tools and technology applied in metal stamping. Advanced machinery-equipped providers can quickly create more accurate and complicated parts. They provide consistent quality and can manage more types of materials. Modern tools also enable creative procedures like electro-erosion cutting, which is necessary for complex and precise components. Make sure your chosen supplier always upgrades their equipment and keeps up with technology developments.

Full Services

Metal parts manufacturing companies with broad expertise will help you to simplify your production line. Have one company handle the whole project, from the initial design to the final packaging. This will save you time and money. To keep things running smoothly, they can do things like designing and making dies, stamping, deburring, and finishing. While working with multiple vendors, there is a chance of misunderstandings and delays. This unified approach reduces those risks.

Customer Services and Correspondence

Quality communication and strong customer service are important factors that people often forget about when choosing a metal stamping provider. A provider that emphasizes clear and timely communication can make manufacturing projects a lot less stressful and uncertain. They should be sensitive to your questions and problems and keep you updated at all phases of the process.

Learn more about the metal stamping process and services at https://www.satellitemetal.com/.

Knowledge and Ability

Metal stamping heavily relies on experience and expertise. Decades of experience allow providers to offer an extensive pool of knowledge and problem-solving ability. They can see possible problems and take care of them before they become more serious. Their knowledge also enables them to provide practical advice on cost-cutting strategies, design changes, and material choices.

Modern Equipment and Technology

The result directly depends on the tools and technology applied in metal stamping. Advanced machinery-equipped providers can quickly create more accurate and complicated parts. They provide consistent quality and can manage more types of materials. Modern tools also enable creative procedures like electro-erosion cutting, which is necessary for complex and precise components. Make sure your chosen supplier always upgrades their equipment and keeps up with technology developments.

Full Services

Metal parts manufacturing companies with broad expertise will help you to simplify your production line. Have one company handle the whole project, from the initial design to the final packaging. This will save you time and money. To keep things running smoothly, they can do things like designing and making dies, stamping, deburring, and finishing. While working with multiple vendors, there is a chance of misunderstandings and delays. This unified approach reduces those risks.

Customer Services and Correspondence

Quality communication and strong customer service are important factors that people often forget about when choosing a metal stamping provider. A provider that emphasizes clear and timely communication can make manufacturing projects a lot less stressful and uncertain. They should be sensitive to your questions and problems and keep you updated at all phases of the process.

Learn more about the metal stamping process and services at https://www.satellitemetal.com/.

Comments

Post a Comment