Top Trends to Look Out for In Metal Stamping

The metal stamping industry is changing at a fast pace. There are several advancements taking place every year. The most trusted companies are leveraging new technology. But what are some of the most exciting trends in the metal stamping industry? Let’s discuss.

The increase in electric vehicles

The world is switching to electric vehicles, including metal stamping opportunities. Several components require metal stamping. Auto manufacturers choose custom metal stamping services to get efficient components for electric cars. These components can be small or large based on different needs. These pieces work exceptionally in adverse conditions, too.

Increasing need for lightweight and strong materials

The automotive and manufacturing industry depends on lightweight components. Today, metal stamping companies rely on lightweight, resilient alloys like aluminum, copper, etc. These companies have in-depth knowledge and can help with advanced technologies. Manufacturing companies get energy-efficient and flexible solutions by working with renowned companies. The use of these alloys helps reduce overall weight without affecting performance.

Sustainable manufacturing practices

Like every other industry, the metal stamping industry also focuses on sustainability. A metal stamping company fulfills customer needs while focusing on sustainable manufacturing practices. These companies rely on strategies such as lesser waste output and smarter energy use. It helps them contribute towards a brighter future. These companies may recycle materials, rely on renewable energy sources, etc.

3D printing technology

3D printing technology has brought innovation to the manufacturing field. You can choose computer design and printers. Various materials are being relied on to create parts for industries like automotive, aerospace, etc. The 3D printing technology and metal stamping help manufacturers get access to complex parts without wasting a lot of time. It also reduces the overall manufacturing cost. It is highly beneficial for prototyping or small-batch production. 3D printing helps reduce several steps in the production process. Hence, industries can benefit from innovative solutions.

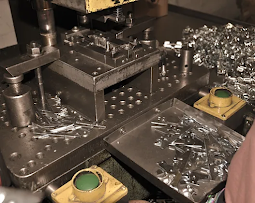

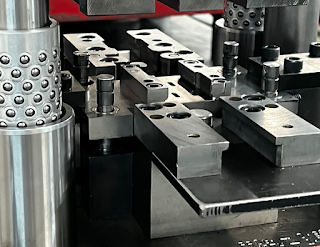

Advanced automation and robotics

Automation has also become popular in the metal stamping industry. Today, companies are relying on cutting-edge technology to reduce production costs. These companies are using sensors to detect defects. It helps offer the most premium quality parts to clients.

If you require metal stamping services, you should keep up with the latest trends. It will help you get the most suitable solutions from a renowned die manufacturing company. This sector keeps evolving based on the latest technology and offers outstanding solutions to all clients.

To get more details, visit https://satellitemetal.com/

Comments

Post a Comment