Why Material Selection Matters in Manufacturing: A Guide to Metals

Manufacturers face a very challenging decision: what metal do they choose for the job? It is not just a matter of selecting what is available or what they are familiar with at metal stamping Canada. The material defines everything. It is nerve-wracking to consider that a small error in material selection can lead to disastrous outcomes.

Imagine the consequences: products failing prematurely, costs skyrocketing, or endangering users. This decision is generally taken at an early stage of design and will be the one that dictates whether the whole project will work or not. So, how do you know what is best among these options? Let us open up this topic and explain what makes this choice so important.

Metal Properties

Different metals boast distinctive features in strength, durability, weight, and corrosion resistance, which are very important for deciding the suitability for specific applications. For example, steel is unmatched for its strength and would be appropriate in structural members of construction or automotive components. But, for an environment with a lot of moisture in the air, metal stamping companies might suggest aluminum, which is better because of its corrosion resistance. Still, the use of the wrong material may lead to some surprising problems.

Match Materials to Application

Knowing the properties of different metals is only one part of the story; the next is their application to the appropriate use. Brass, for example, has excellent machinability and low friction; it will become unavoidable in the manufacture of detailed components for which it is essential to hold minute details. Titanium, in contrast, may be the material of choice for the strong-but-light application of aerostructures, where both strength and weight are critical.

Making the Most of Cost and Performance

Thus, material selection also involves the act of delicate balancing between cost and performance. High-performance metals, such as titanium, indeed have fabulous performance, but they come at a price. You don’t have to choose them for every job. For most things, acceptable performance can come from much cheaper materials like carbon steel or aluminum.

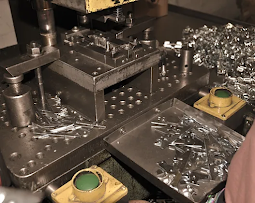

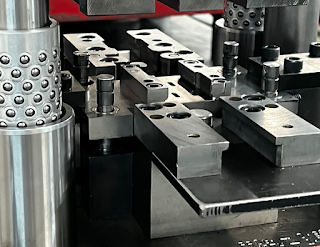

About Satellite Metal:

Satellite Metal is a metal stamping manufacturer specializing in high-quality metalwork. It offers solutions for simple, complex, and custom parts. Its state-of-the-art equipment lets the company serve diverse industries with quality control and ISO 9001 accreditation for flawless products from design to finish.

For more information, visit https://satellitemetal.com/

Comments

Post a Comment